Aben Resources Announces Update on Slocan Graphite Project

Aben Resources Ltd. has shared an update on its Slocan Graphite Project, which spans 2,387 hectares and is located 34 km northwest of Castlegar.

The Project has outstanding infrastructure, including forestry road access to the property, a high-voltage transmission line within 1.2 km of the property limits, and an existing graphite processing facility and amenities within 1.5 km west of the property and owned by Eagle Graphite Corporation.

It is one of the only two natural flake graphite production facilities in North America.

Slocan Graphite Project

The Slocan Graphite project’s mineral exploration permit is still being reviewed by the Ministry of Mines. When climate and ground conditions permit, the Company plans to undertake ground exploration on the land. Due to the quantity of snow this winter and the resulting moist ground, the program will most likely begin in late June.

The Ministry of Mines has also given the Company an exemption letter to perform an IP survey before the permit is granted. In addition, depending on the receipt of the permit, a drill will be ready for the project in late August.

Aben has an exclusive right to earn a 100 per cent interest, less two per cent Net Production Royalty (“NPR”) in the road-accessible Slocan Graphite Project located 34 km northwest of Castlegar.

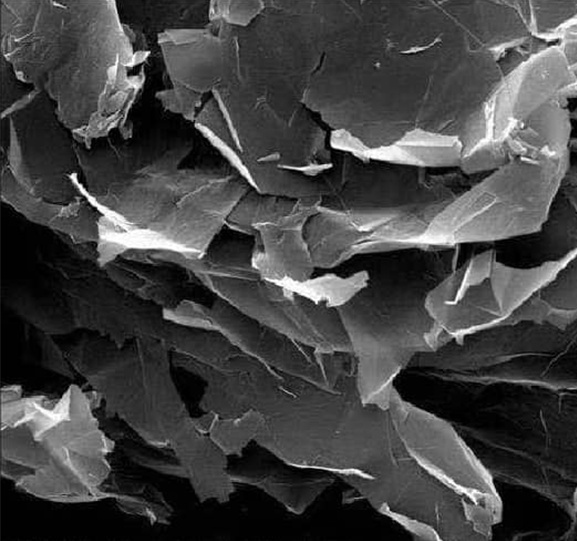

At the Tedesco Zone of the 2,387-hectare Slocan Graphite Property, numerous huge flake graphite-bearing outcrops (high values of 3.36 and 4.43per cent organic carbon) correlate with a strong conductive anomaly discovered in 2010 and estimated to extend up to two km from known surficial occurrences.

The Slocan Graphite Project has excellent infrastructure, including a high-voltage transmission line within 1.2 km of the property boundaries, an extensive network of forestry roads on and around the property, and a graphite processing plant and facilities 1.5 km west of the property (owned by Eagle Graphite Corporation).

About Graphite

Natural flake graphite is the fastest-growing product category, and it will continue to lead with a robust growth rate of 9.5 per cent in terms of value between 2021 and 2025.

Between 2021 and 2025, batteries are expected to expand at the fastest rate of 17.9 per cent in both value and volume. HEVs can have up to 10 kg of graphite, whereas EVs can have up to 70 kg.

Synthetic graphite is now the most used material for battery anodes. However, due to its cost-competitiveness and performance, natural flake graphite has seen a dramatic change in recent years.

For rechargeable batteries, graphite is the most preferred anode material, and the battery segment is expected to generate an incremental opportunity worth US$4.6 billion between 2020 and 2025.

The Asia Pacific was the top consumer of graphite in 2019, and the region is predicted to expand 9.1 per cent in value between 2021 and 2025. Due to environmental concerns, China’s graphite manufacturing is expected to consolidate.

New businesses are joining the graphite industry, particularly in the processing of natural flake graphite. Graphite is regarded as a green energy and technology resource.

Comments