How to bring electric vehicles to the mass market

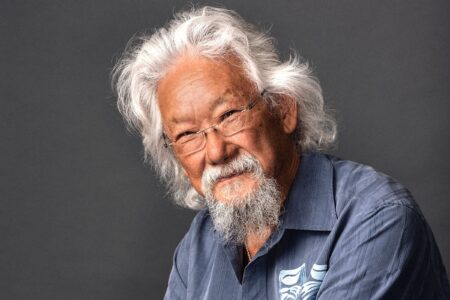

By David A Gabel, ENN

Automakers must figure out how to avoid having their electric vehicles suffer an agonizing death in the niche market, and instead, figure out how to get 100 million EVs on the road.

The single biggest complaint against electric vehicles is their lack of range, so the batteries must be addressed. They must be cheaper, safer, last longer, and contain higher levels of energy.

Scientific laboratories around the country are studying how to make these improvements. In particular, the Lawrence Berkeley National Laboratory (Berkeley Lab), which is recognized as a top lab in the country for battery research, is working to make incremental improvements to batteries as well as come up with breakthrough technologies.

Researchers hope to make electric vehicles as common place as electrical handheld devices and computers.

“I think with incremental improvements in batteries, engineering advances in the car and support from the government, these are all things that will make it a reality,” says Berkeley Lab scientist Marca Doeff. “And there’s considerable enthusiasm among the population as a whole, so I think it’s going to happen.”

Battery technology is extremely complex, filled with trade-offs. For example, by increasing the energy density so it contains more charge, the life of the battery will be shorter. Also, if you wanted to make a safer battery, the energy density will be lower. These are among the many issues facing the development of lithium-ion batteries.

The researchers are striving to reach the goal of the Department of Energy’s FreedomCAR: a plug-in hybrid electric with a range of 40 miles and a battery life of 15 years.

One reason why the government is pushing this research is to bring battery manufacturing back to the United States. About 20 years ago, nearly all lithium-ion battery production moved to Asia. In order to beat China, Japan, and Korea, the US needs a big breakthrough.

Another prohibitive factor which may keep electric vehicles from the mass market is that they are costly. The batteries are currently $1,000/kilowatt hour and the DOE’s goal is to bring that cost down to $150/kilowatt hour.

Many researchers are skeptical of the DOE’s goal; it would be like all-electric vehicles having the same range as typical cars, about 300 miles.

To cut costs, battery makers need new sources of raw materials. For example, the cobalt oxide used for cathodes in lithium-ion batteries is expensive and comes from politically unstable regions. Options being explored for cathode material include lithium iron phosphate, lithium manganese oxide spinel, titanium, and aluminum.

Sixty per cent of the batteries cost comes from the raw materials and forty percent from the manufacturing process which can have up to sixty steps. If cheaper materials can be secured and the manufacturing process streamlined, real cost savings can be realized.

Then, perhaps, electric vehicles will be widely adopted. At this moment, too many people are invested in making sure EVs make it. The United States does not want them to suffer another agonizing death.

- For more information on Berkeley Lab’s battery research: http://www.ucop.edu/sciencetoday/article/2565

Comments